Processing Efficiencies

Our Base Systems Include:

- Full automation including process recipe creation, data logging and storage

- Independent thermal controls for extractor vessels and separator vessels

- (3) 2.5-liter separator vessels

- CO2 Recirculation (closed loop)

- CAT Triplex pump (autonomous pressurization and operation up to 10,000psi)

- Legacy chiller package

- Water and water-soluble compound capture system

- Batch and continuous mode extraction operations

- Automatic CO2 re-fill from high-pressure cylinders

- 1 year technical/parts support

We Also Offer the Following Options:

- Co-Solvent Injection

- Cylinder manifold to interconnect 4 gas cylinders

- Thermostat controlled heating blankets for cylinders

- Installation and commissioning by KiiNjA personnel

- Auxiliary set of 3 industrial glass sample containers

- Auxiliary set of pressure vessel end-caps Qty of 10

- Specialty tools for operation and maintenance

- Consumable parts and recommended spare kit

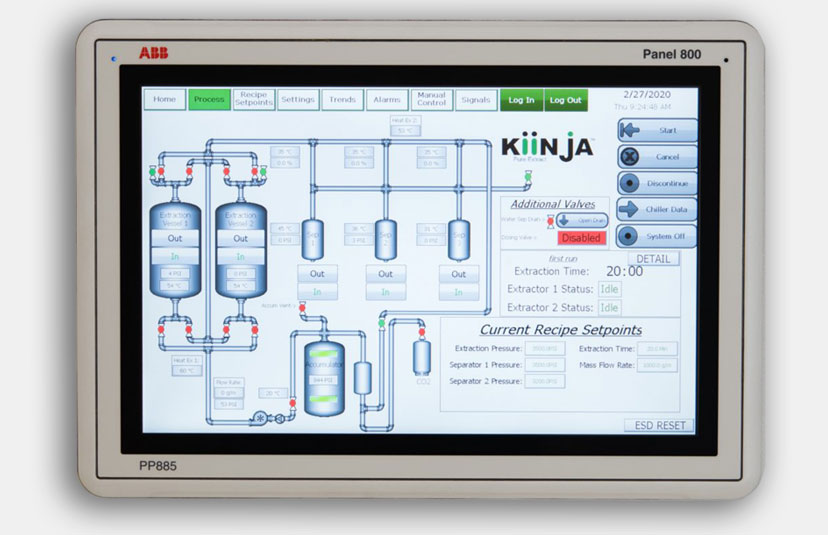

Complete Automation

- COMPLETELY automated for unattended operation and TOTAL safety

- All process valves are closed loop position feedback controlled by the PLC (Programmable Logic Controller) system

- Extractor and separator vessels clamping (locking) and unclamping (unlocking) with position feedback monitored and controlled by the PLC system

- All thermal, pressure and sealing of the COMPLETE system is controlled and monitored by the PLC system

- No pressure end caps for operator to remove or handle

- All vessels are continually supported by a mechanical beam connected to the main frame of the machine to avoid any heavy lifting or vessel manipulation (no lifting required)

- Precision control of extraction pressure, with rapid adjustment capability

Water Phase Recovery

Water and Water-Soluble Component Capture System

- Condensation of aqueous soluble compounds

- Capture and removal of aqueous phase (water) and aqueous soluble compounds (i.e. terpenes and flavonoids)

- Dedicated heat exchanger for temperature modification and fluid condensation

- Cyclonic separation vessel for efficient removal of aqueous phase from CO2 stream

- Vessel thermally controlled for uniform temperature regulation and control

Safe CO2 Extraction

Key Safety Features on the Kinetic Series:

- Fully automated for unattended operation and total safety

- All process valves are computer controlled with closed loop position feedback – no guess work on the position of the valves –

- Extractors and separator vessels clamping (locking) and unclamping (unlocking) with position feedback monitored by the PLC system – no room for human error

- All thermal, pressure and sealing of the COMPLETE system is controlled and monitored by the PLC (Programmable Logic Controller) system

- Non-isolatable pressure safety relief valves

- Non-isolatable overpressure safety rupture element

- Pressure vessels designed to American Society of Mechanical Engineers (ASME) standards and national code requirements

- All electrical components are NRTL, UL or Industry Group complaint certified

- System is designed by a certified Professional Engineer

Get in touch with our sales team to find out everything you’ll need to know about CO2 extraction equipment. We will help you estimate shipping costs as well as daily operations costs and tell you in detail about our extraction process.

Get in Touch